|

WWII Aircraft Manufacturing Sites-Home Canada Aircraft US Aircraft US Cross Reference US Airships US Engines USA Gliders Propellers Plant Photos US WWII Aircraft Costs WWII Aircraft Manufacturers' Literature US Aircraft Assembly Plant Numbers US Aircraft Modification Centers Photos of WWII Aircraft Manufacturing Sites Today Aeronca (Now part of Magellan Aerospace) at Middletown, OH Airport (Hook Field). - These photos were taken in June 2009. During WWII Aeronca manufactured its own L-3 and the Fairchild PT-19 and PT-23 under license at Hook Airport. It does not appear that any of the original manufacturing plants still exist. All of the current facilities look to be new.

AeroProducts (later utilized by Inland Division of GM, then Delphi) at Vandalia, OH - This plant was demolished in the spring and summer of 2008 and no longer exists.

Beechcraft at Wichita, Kansas Plant 1 (Now Hawker Beechcraft) - Beechcraft had and still has its headquarters, engineering, and manufacturing at its own airfield on the east side of Wichita, KS. The photo below, taken in the rain, is a corner of its Plant 1, which would have been the center of its operation during WWII. Now the Hawker Beechcraft operation is on all four sides of the airport.

Bell at Marietta, GA B-29 Plant (Lockheed since 1951) Air Force Plant #6 - This plant built a total of 668 B-29s during WWII. 311 of the 668 were B-29Bs. Marietta was the only plant that built the B model, which was stripped of turrets, guns and armor except for the tail position and were optimized for low level night bombing and were 7,0000 pounds lighter and ten miles an hour faster than the normal B-29.

Bell at Wheatfield, NY P-39 and P-63 Plant - This 600,000 square foot aircraft manufacturing plant was built on the site of the current Niagara Falls, NY Airport. In 1941 this plant produced the bulk of the P-39s and all of the P-63s, along with the post-war jet aircraft, rockets, and helicopters. In 1951 the helicopter division moved to Ft. Worth, TX. What is known to the local residents today as the former Bell Aerospace Building is occupied by Lockheed Martin Maritime Systems and Sensors. This appears to be a continuation of work Bell did on hovercraft in the 1960's. Several other companies are also utilizing some of the space, while some parts of the plant are falling down.

Boeing at Renton, Washington B-29 Plant - This plant was originally built by the Navy to build Boeing XPBB-1 Sea Ranger seaplanes. However, by the time the plant was built, the Navy realized the true value of aircraft carriers and land based aircraft like the B-24 for patrol. So only one Sea Ranger was built, which became known as the Lone Ranger. The Sea Rangers would have come out the plant doors and then been launched down ramps into the lake. With the Navy not needing the Sea Ranger, the Army took over the plant for much needed B-29 production. (The Renton B-29s were actually B-29A models due to the fact that their wings were attached differently to the aircraft than the ones built at Wichita, Omaha, and Marietta. Due to this, they had one less fuel cell and had a shorter range than the others.) The world's only flying B-29, "Fifi", operated by the Commemorative Air Force was built here and came out of these doors.

Today there is a municipal park squeezed in between the west side of the plant and the east side of the river. One can park there and walk out to the dock.

Boeing at Wichita, Kansas B-29 Plant - This plant is now Boeing Integrated Defense Systems-Wichita Programs and Spirit Aero Systems. The first photo was taken from the tower at the Kansas Aviation Building. This was the original terminal at Wichita Airport which during WWII became a huge complex of B-29 manufacturing and air base. Boeing Integrated Defense Systems at Wichita now works on such projects as Air Force One, Airborne Laser Lab, B-52 Fleet and E-4B Support, and the KC-135 re-engine program. It appears to occupy the complex on the southwest apron and a new engineering building southwest of that. Spirit Aero Systems now has the main manufacturing plant that built B-29s during WWII where it currently builds subassemblies for Boeing. No finished aircraft are made at this location anymore. After Boeing purchased Stearman at this location in 1938, 1,644 B-29s came out of this location at a rate of 4.2 per day after production started in 1943. The Boeing Stearman Kaydet for both the Navy and Army Air Corps were also built on the complex. In 1951 the production of over 1,300 B-47s began at this plant; and starting in 1970 it began building forward fuselage section for Boeing commercial aircraft and 90% of the 737 was built here. This factory complex is located on the southwest side of the airfield. McConnell AFB is the east side, and to the north on the west side is the Kansas Air National Guard.

Brewster which became the Naval Air Development Center and then the Naval Air Warfare Center, is located at Johnsville (Warminster), PA. http://www.navairdevcen.org/Pix/aerial.html - Brewster Plant is in the left center of the photo. All of this has now been developed and looks to be condominiums, apartments, and some light industrial. Buick Engine Plant at Melrose Park, IL Buick built this plant during WWII for the manufacture and assembly of Pratt and Whitney R-1830 engines for the Consolidated B-24s. After the war International Harvester (Now Navistar) purchased the plant for engine manufacture. It is still operating in that mode.

Consolidated-Vultee at Nashville, TN - As of 2019, this plant is now owned by TECT Aerospace of Wichita, KS. It was obviously a rainy day in July 2010 when I took these photos, all from inside the vehicle.

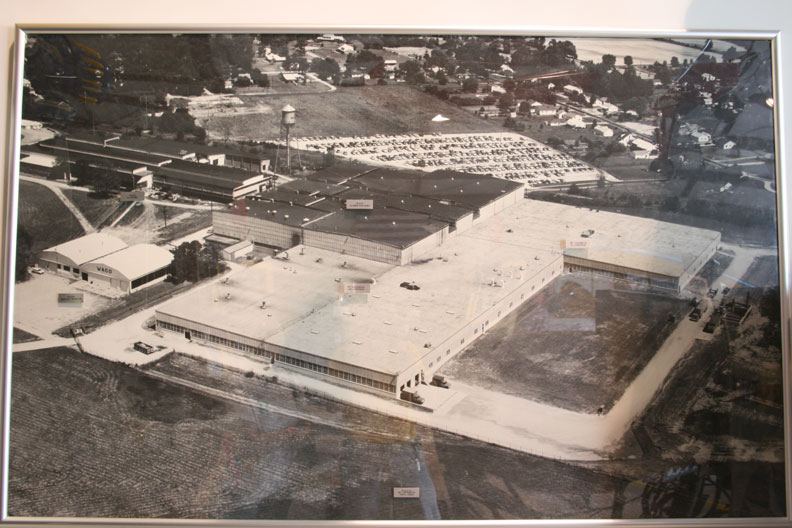

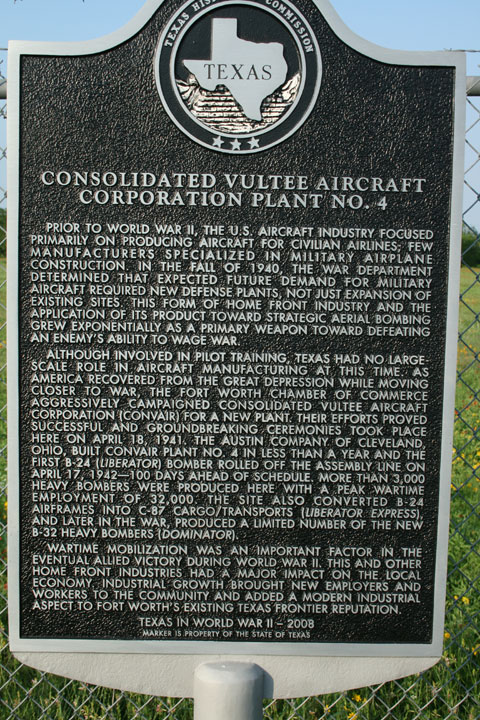

Consolidated-Vultee at Ft. Worth, TX - This is now an Air Force Plant operated by Lockheed-Martin. This was the main manufacturing plant for B-24's by Consolidated during WWII. Later when Convair was purchased by General Dynamics, the F-111 and F-16 were built here. Now it is the focal point for the manufacture of the new F-35 Joint Strike Fighter.

Curtiss-Wright (Now Columbus International Airport Business Park) Plant at Port Columbus Airport, OH - Curtiss built SB2C Helldivers, S03C's, SC-1's and SC-2's for the US Navy during WWII. The business park is occupied by multiple businesses and aviation companies. Columbus has put to good use this asset left over from WWII which was built by the Navy. After WWII North American used the facility to build Furies, Vigilantes, Buckeyes, and Broncos.

Dodge (Chrysler) R-3350 Engine Plant at Chicago, IL - This plant produced 18,349 Wright Radial Engines for the B-29 program in WWII and consisted of 19 total buildings that covered 82 acres and contained 9,000 machines. In other words, this was a huge complex. After WWII Dodge did not need the facility and it was turned back over to the government. Later Ford Motor Company used it which is why the current shopping mall located in some of the original buildings has been named Ford City Mall. Other parts of the complex are owned by Tootsie Roll and other miscellaneous businesses.

Douglas A-26, A-24, and B-24 Plant at Tulsa, OK - This is all that remains of the original plant that was 7/8 of a mile long and was originally built to assemble B-24s with parts from the Ford Willow Run Plant. Photos were taken late in the day with the sun going down behind the plant.

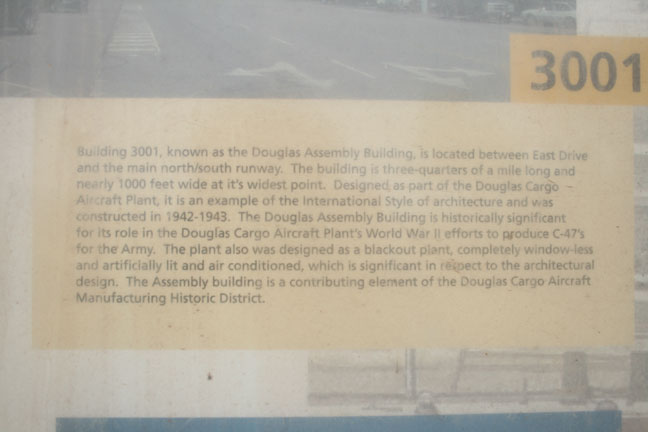

Douglas C-47 Plant at Oklahoma City, OK - The building is still there and now located on the east side of Tinker AFB which is southeast of Oklahoma City. The series of photos below were taken from an outside display board at the Air Park located at Tinker. The displays are covered by Plexiglas, so the photos are somewhat blurred.

Fairchild Plant at Hagerstown, MD - This is now an Air Park with commercial tenants.

Fisher Body Cleveland Plant Aircraft Division Plant 2 (Now the International Exposition Center) at the Cleveland Airport, OH - This plant was built in 1942 to build 200 B-29 bombers. While under construction, the US Army Air Force changed plans and moved the B-29 production to the Martin Omaha, NB plant which had been making the B-26. Instead, Cleveland Plant 2 became a primary parts supplier the B-29 project. Construction of the eight XP-78 and six P-78A Eagles did take place here along with special conversions such as the B-39, which was a B-29 with Allison V-3420 engines and converting the Douglas B-19 to the Allisons. Several historical sources have misinterpreted history and claim that Cleveland Plant 2 built B-29s. The plant was built for that purpose, but never produced any B-29s due to the changing demands of the war. What it did produce was 13,772 B-29 engine nacelles.

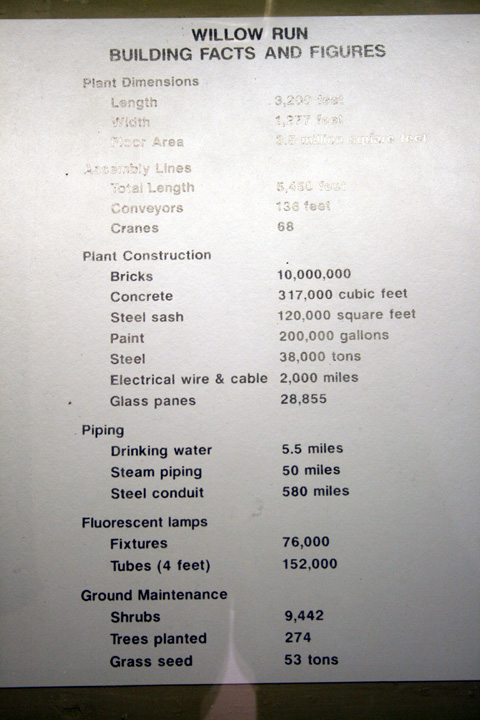

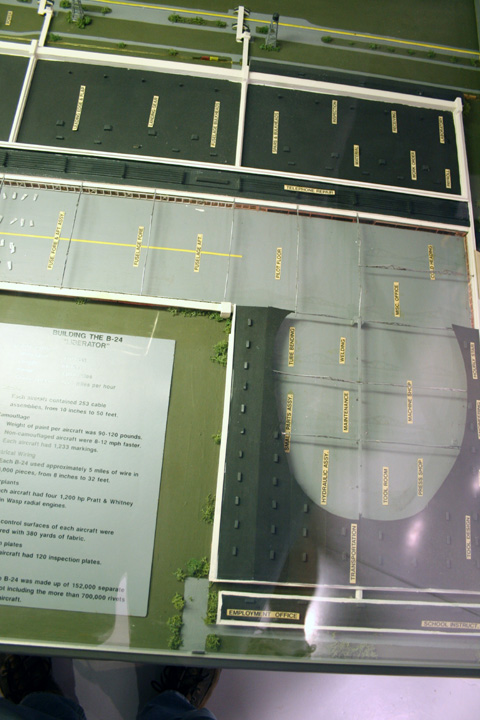

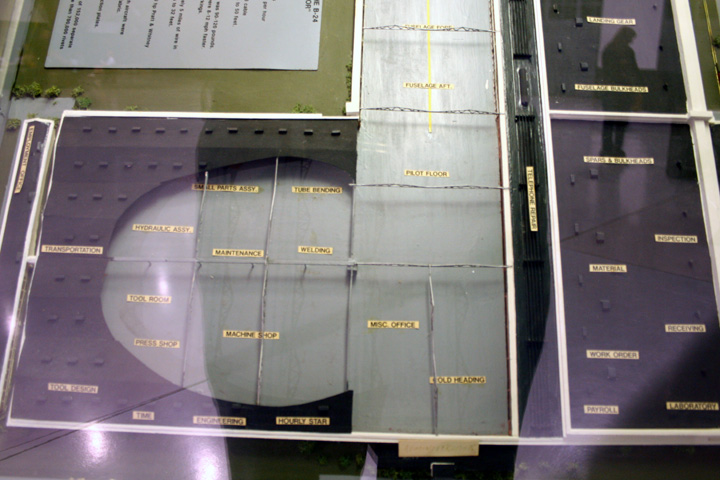

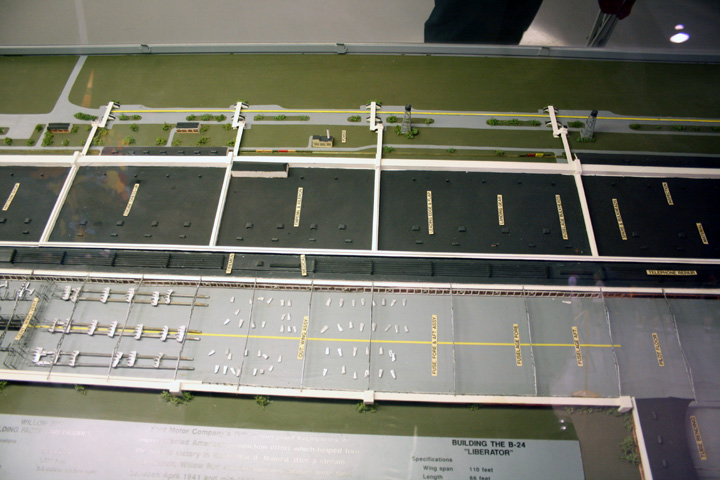

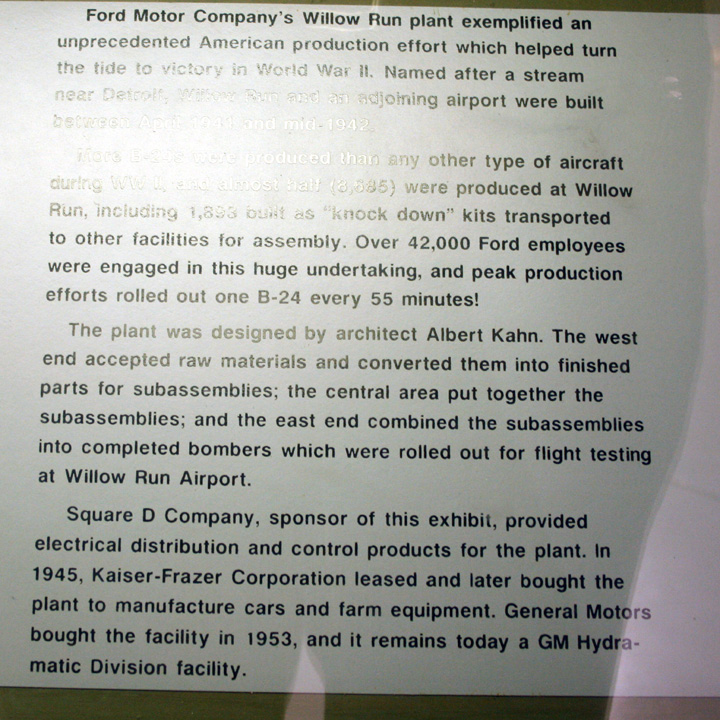

Ford B-24 Plant at Willow Run, MI - With the exception of the paint hangar at the end of the line, this plant has been razed. Photos will be left on this site for historical purposes.

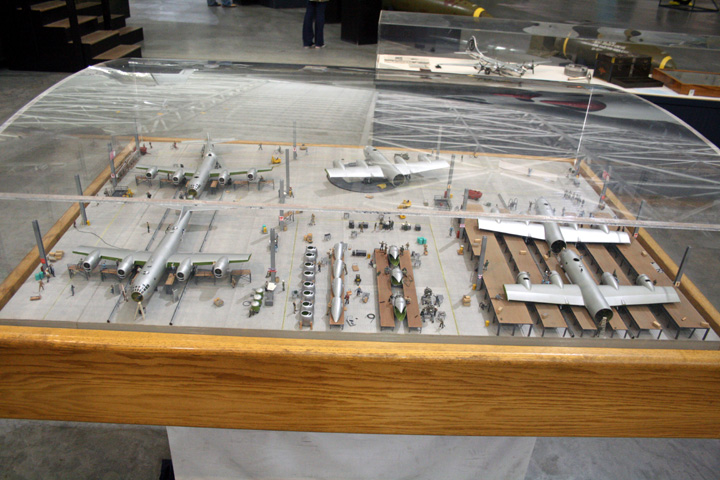

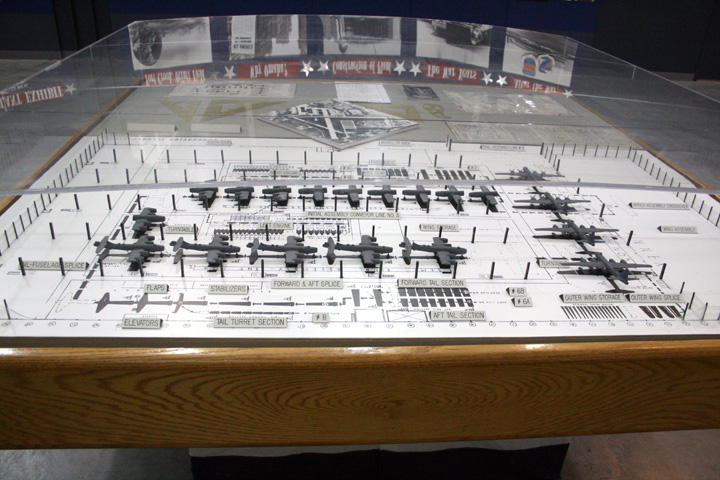

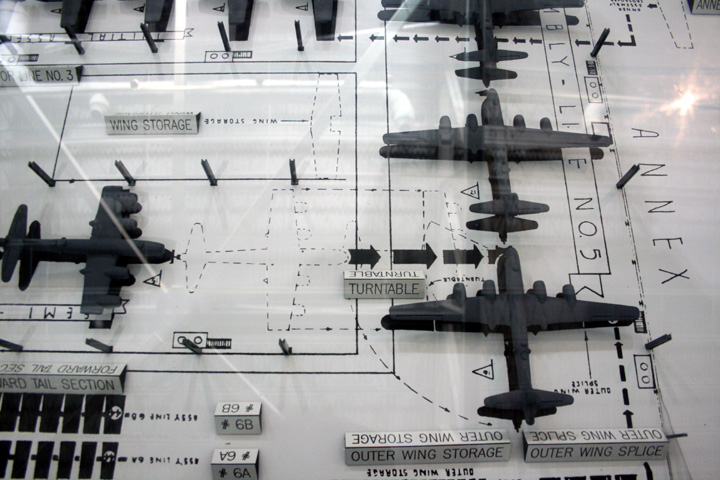

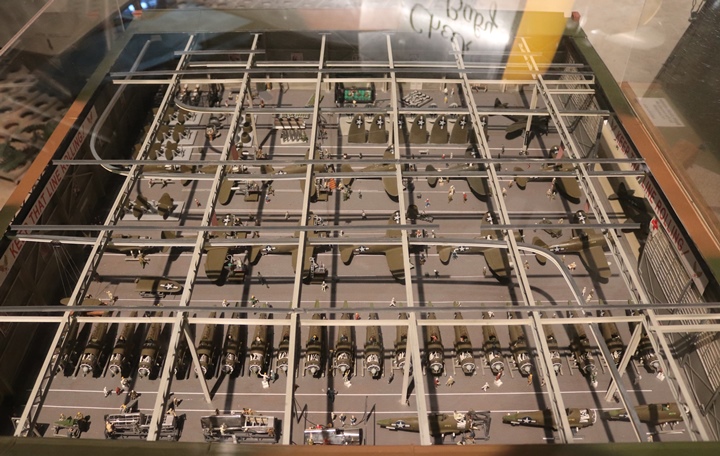

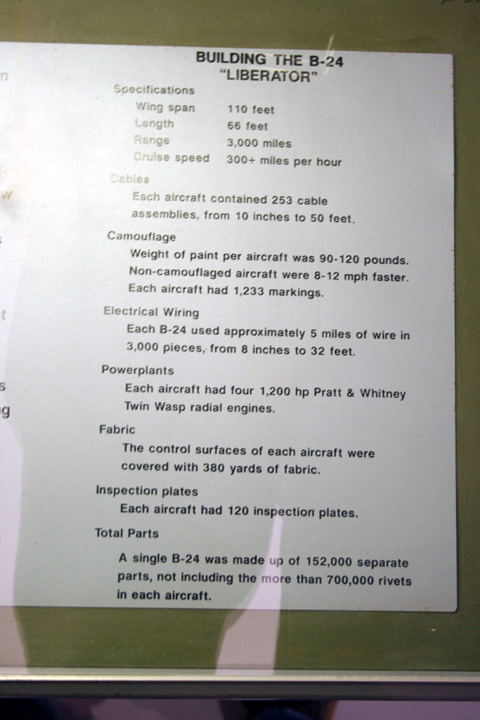

The following photos are from a model display at the EAA Museum in Oshkosh, WI.

Goodyear (Now Lockheed-Martin) Airdock at Akron, OH - The red area on the end of the Airdock caught fire in August of 2006. The photo was taken in July of 2007.

Updated photos taken in June of 2008. Fire damage has been repaired.

Goodyear Blimp Hangar at Wingfoot Lake, OH - Most of the WWII airships were built at this location. There were other buildings but this one still remains. It is the current home of the Goodyear Airship "Spirit of Akron".

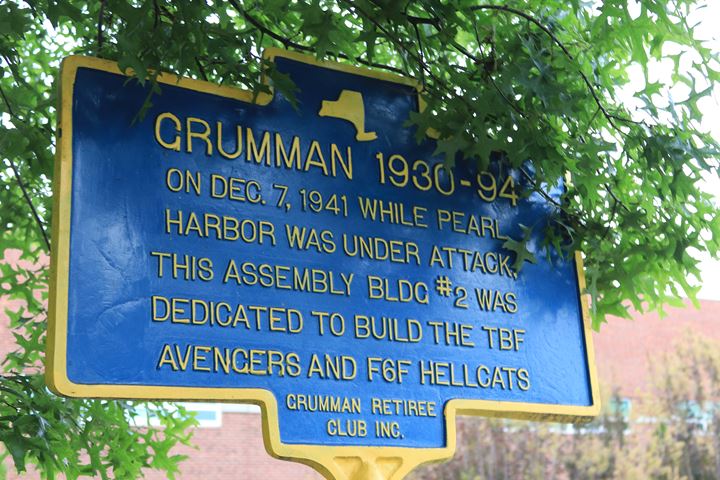

Grumman Plant 2 at Bethpage, NY - Much of the original World War Two Grumman Plant 2 and post war buildings are still in existence, although they have all been repurposed for other purposes rather than the building of F6F Hellcats and TBF Avengers that were built here 75 years ago. There is no evidence of the former runways on the east side of the complex.

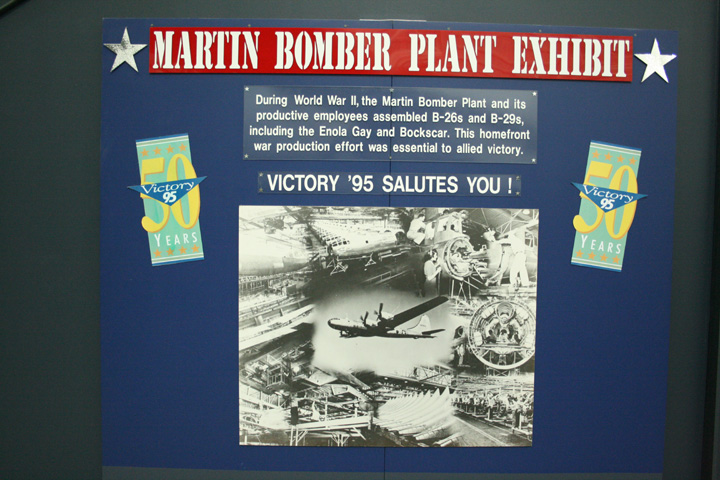

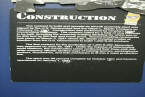

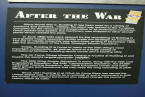

Martin Plant at Omaha, NE - The photos below were taken at the Strategic Air and Space Museum in Ashland, NE which is located right off of I-80 about 20 miles west of Omaha. This is an excellent museum and should be a stopping point of any aviation enthusiast traveling across the country on I-80. Included among all the aircraft displays are models of the Martin Bomber Plant in Omaha that was originally built to produce B-26s but was then converted to one of the five plants to build the Boeing B-29 Superfortress. The Omaha plant went on to build 515 B-29s, including The Enola Gay and Bockscar, after completing construction of 1,585 B-26s for the war effort. The Omaha Plant was a reverse image of the plant built by Martin in Middle River, MD to also produce the B-26. Below are photos of this great display at the museum. Today the plant still exists and is located at Offutt AFB in Omaha.

Nash-Kelvinator (Mt. Hope Ave. Plant) in Lansing, MI - This building is located at the corner of South Washington Avenue and Mt. Hope Avenue. Originally built by REO, which was about a half a mile north on South Washington Avenue, it was used by Nash-Kelvinator during WWII to produce 158,134 Hamilton-Standard propellers. I grew up a mile away and walked by this plant for three years going to Junior High School. Then I drove by it for five and a half years when I went to college. I was unaware of this building's historical or family significance until early 2011. My grandfather worked here during WWII and was a foreman in the propeller balancing department. The location of the plant allowed him to walk to work and save valuable rationed gasoline. After WWII, Motor Wheel Corp. occupied the building for a while until it moved out to the north end of Lansing. Around 1960-61 this was the location of the first discount / big box store in Lansing. I do not remember the name of store, but it was the predecessor of the K-Marts and others we have today. That lasted for a short time and then, I believe the plant was occupied by a drop forge, of which we had several in Lansing supporting Oldsmobile. It now houses multiple companies in what is called the Mid-Michigan Industrial Center.

Nash-Kelvinator (South Cedar St. Plant) in Lansing, MI - This is where the original Hamilton-Standard propellers where made before the operation expanded out to the larger facility on Mt. Hope Ave. It was then used for the manufacture of the propeller hubs. After WWII it was purchased and operated by John Bean making fire apparatus until the 1970's. Now it is a home to several different businesses. It may also have originally been built by REO which was located on the other side of Cedar Street.

North American in Dallas/Grand Prairie, TX - This government-built and owned plant was used by North American starting in 1941 to build AT-6's and later then built P-51's and B-24's under license from Consolidated. After WWII, North American left the facility and Vought moved in from Connecticut. Vought was still located at this location when I visited, and it was it's world headquarters. This plant is just one block south of the main street in Grand Prairie and dominates the downtown area. Vought no longer manufactured aircraft here nor at its other locations but is a supplier of subassemblies to the remaining aircraft manufacturers. The former NAS Dallas is adjacent and to the east of Vought. With its closure and move to the former Carswell AFB in Ft. Worth there is no longer an active runway at this location. The last flying aircraft built at this plant would have been the A-7 Corsair. January 2023 Update: This facility is in the process of being torn down. Triumph was the last owner of the plant which was manufacturing parts for the Boeing 767. Due to severe financial issues, Triumph closed many of its facilities and outsourced the work to other companies in 2020. Work at this plant in Grand Prairie ended in 2021. Currently, the plant is being razed for a new Home Depot warehouse and transportation ion center that will be located on the 315 acre site. On December 27, 2022, one of the remaining empty buildings caught on fire and burned to the ground. This is all such an ignominious end for a plant that contributed so much to the winning of World War Two.

Packard Auto Company in Detroit, MI. - This is the manufacturing location of 54,714 Rolls-Royce Packard V-1650 Merlin Engines. The plant is located at the corner of East Grand Boulevard and Concord Street. The plant is on both north and south sides of East Grand Boulevard and west Concord. Unfortunately, the facility is very dilapidated and is in a neighborhood similar to those seen in the movie Gran Torino. Packard went bankrupt in 1954. Apparently no one has the funding to raze the buildings. It looks like various businesses and enterprises have utilized the structure since Packard went out of business. There does not appear to be anyone using it now. From an architectural and historal perspective, this is an important structure as it was designed by Albert Kahn, a prominent industrial architect who designed many factories, including several of the WWII aircraft plants, until his death in 1942. This plant was built in 1907, and the design by Kahn introduced the concept of replacing wood walls with reinforced concrete that allowed more open space for manufacturing. Many of his designs were used in Detroit and he is known as the "Architect of Detroit". After designing this plant, some of his other work in Detroit included the Ford Highland Park Auto Assembly Plant, the massive Ford River Rouge Complex, the Warren Tank Arsenal, and the Ford Willow Run B-24 Plant.

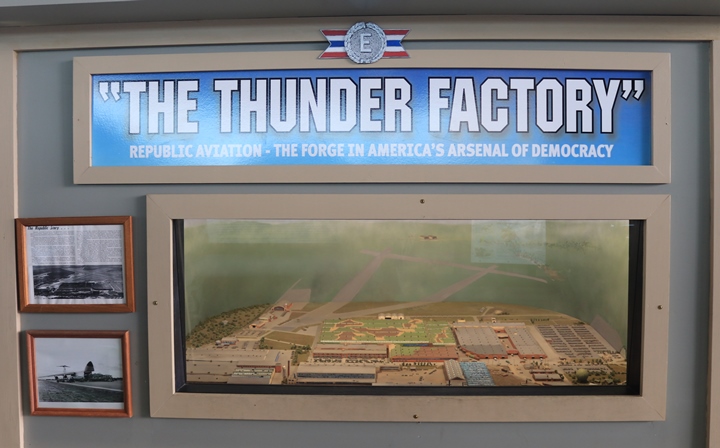

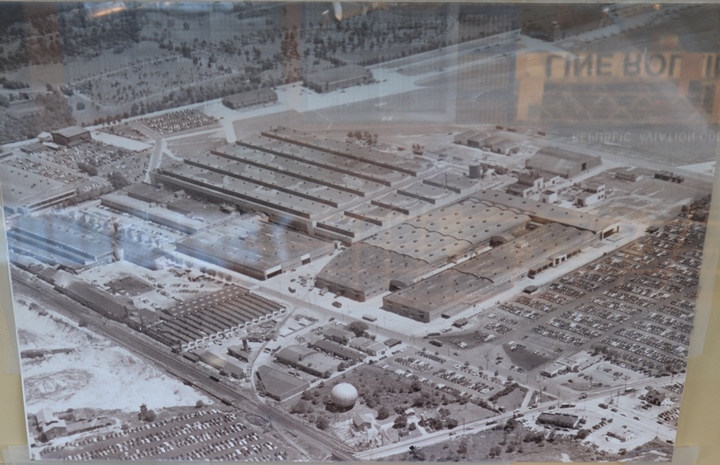

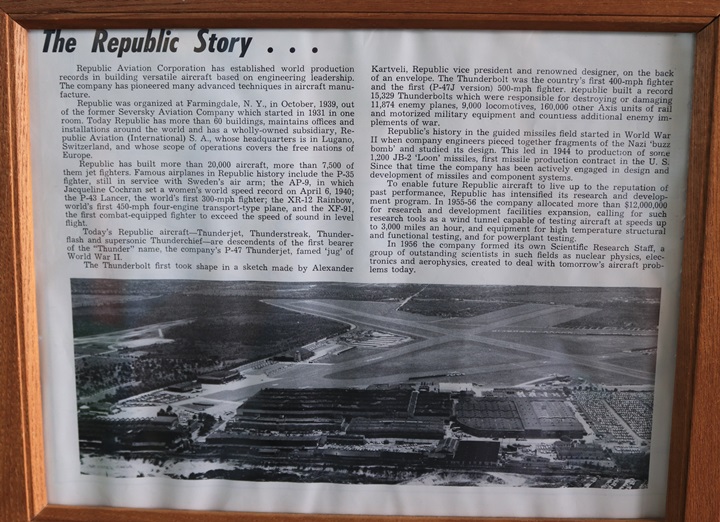

Republic Aircraft Facility at Farmingdale, NY on Long Island: This former factory complex has been razed and the land re-purposed for a large retail complex. Two hangars still remain on the east side of the former complex. One is utilized by the American Power Museum and the other is used for a local flight school.

Inside the American Power Museum is a large display on the former company that occupied the site.

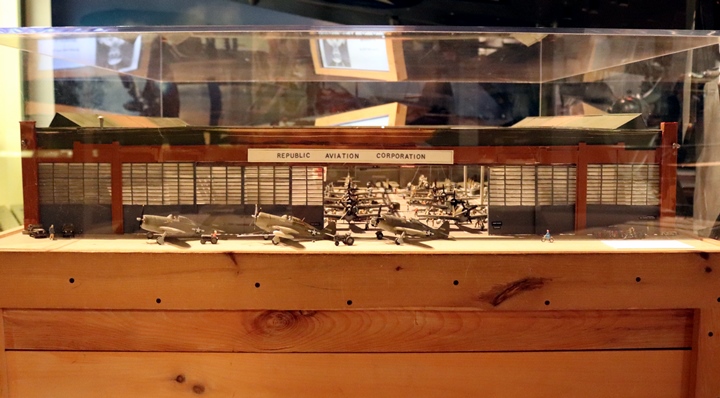

The Cradle of Aviation Museum in nearby Garden City, NY also has a model on display of the Republic final assembly hangar.

Republic Aircraft Facility in Evansville, IN - After WWII International Harvester used this facility until 1955 when Whirlpool took ownership. In 2010 Whirlpool closed the facility for production and moved the operation and jobs to Mexico. When I was here in April 2011 there were still a few persons working in the office area.

Stearman Aircraft facility in Wichita, KS. - This is the hangar that was the Lloyd Stearman initial production facility. It is now located and preserved on the premises of the Kansas Air National Guard Base. These photos were taken from the control tower of the old Wichita, KS airport terminal facing north east. The tower has tinted windows, so the photos have a green tint. In the background across the runway is McConnell AFB.

Waco Aircraft facility in Troy, OH - The plant is still there, east of I-75 at the OH State Road 55 interchange on Archer Drive.

WWII Aircraft Manufacturing

Sites-Home Canada Aircraft

US

Aircraft

US

Cross Reference

US Airships

US

Engines

USA

Gliders

Propellers Plant Photos

US WWII Aircraft Costs

WWII Aircraft Manufacturers'

Literature

US Aircraft Assembly Plant Numbers

US Aircraft Modification Centers |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

.

.