|

2015 Airshows

Titusville (Tico), FL

Virginia Beach, VA

Seymour Johnson AFB, NC

Halls, TN

Warsaw, IN

B-29 Air Power Tour Fort Wayne, IN

Thunder over Michigan, Bellevue MI

Thunder over Michigan Warbird

Photo Review

Warbirds at the Willow Run, MI Airshow 2015 -

August 29-30, 2015 (Photos taken 8-29-2015.)

Every year the Thunder over Michigan Airshow

brings to the Midwest an outstanding and varied group of warbirds and

2015 gave us a totally different venue than past events, with two sets

of aircraft that flew in the event; fighters and bombers.

For the fighter group there were P-51s,

Corsair, Fw-190, and Spitfire. The bombers were really the

featured group with Mosquito, Lancaster, B-25s, B-17, B-29, PV-2, PB4Y,

and A-26. As in the past, there were ample low fly-bys of both

groups to make any warbird enthusiast go home with a smile on his/her

face and fond

memories of the event. The following are some of the highlights

of the show, and are not inclusive of all aircraft on the ramp or flying

in the show, as I have attempted to pick out a few that give a flavor of

the event. As in 2014, I have added information on how the

American automobile industry contributed the the building of many of the warbirds at the show, not just the contribution of Ford building B-24s

on the west side of the field during WWII, or Packard's building of

Rolls-Royce Merlins in downtown Detroit, which are both emphasized by

the narrator to the exclusion of all others.

In 2014 the Yankee Air Museum was able to

purchase a portion of the former and historical Ford B-24 plant on the

west side of the Willow Run airport that will be turned to a large

aviation education museum. At the airshow for the past couple of

years the narrators have spent time each day talking about the saving of

this portion of the plant, and its historical role in the defense of the

United States during the Second World War. Below are several

photos of the plant that produced 8,684 B-24 Liberators.

This photo was taken in 2014 at the show,

which shows the open steel structure to the north of the museum area as

the plant was being razed.

This photo was taken looking at the same

location but this year only the museum section is all that remains. This is all that

remains of one of the largest manufacturing plants of WWII. (There

are several plants across the country that claim this honor.)

On June 27th of this year the Yankee Air

Force held an open house for those interested to come out and see the

remains of the plant in its unaltered form, before coming a museum.

Looking south from the north end of the

building. One of the Rosie the Riveter tour guides told me the

doors had been designed to be large enough for the B-29. This is

only one of two bays, with a similar one to the right, or west of this

one.

This photo was taken at same location as the

last except one is looking west at the concrete floor of the former plant that runs

all the way out to the flag poles in the distance 3,200 feet away.

On June 27th there were no walls on the west or north side of the

structure, but since then the walls have started to go up to fully

enclose the building for the new museum.

The show narrators are correct on historical

aspect of the former bomber plant, and at the same time the Yankee Air

Force must be commended for the excellent job it has done to raise to

date $6 million dollars to purchase the building and start the

restoration, which will cost another $10 million to complete. But,

as was noted last year by this author in the 2014, the Ford Bomber Plant

has unfortunately over shadowed the larger contribution the entire

US automobile industry made to the winning of WWII.

The total dollar value of the B-24s that came

off the Willow Run assembly line had a value of $1.14 billion out of $29

billion that the entire US auto industry produced for the winning of the

war, or 4% of the total. Not insignificant for one plant and one

product, but there is still the remaining 96% or $28 billion that gets forgotten.

During WWII General Motors produced $12 billion in war

contracts, Ford Motor Company came in a far second with $3.9 billion in

war output, and Chrysler was not far behind in producing $3.5 billion in

defense products. The only other dollar value my research has

found is that Willys-Overland in Toledo, OH produced $730 million in

nineteen wartime projects, doing a lot more than making Jeeps. A

good percentage of what the American auto industry produced was for the

aviation industry, and many examples of its contribution in making US

warplanes was on the ramp at the 2015 Thunder over Michigan Airshow.

As in 2014, I will as usual report on the aircraft and the show itself,

with added commentary on the contribution of the American auto industry

to specific aircraft.

The Ramp.

This year the airshow staff at Thunder focused on bombers, not any

specific one as in years past, but a collection of individual types.

Here we find the Avro Lancaster, B-17 "Memphis Belle", A-26B and the

PV-2 Harpoon "Attu Warrior".

This rare PV-2 Harpoon is one of only two

currently flying, and if I am not mistaken, this is its first appearance

at Thunder. Hopefully it is not the last as it is such a great

looking aircraft.

US Auto Industry Contribution: Ford R-2800 engines and

Chrysler built cockpit enclosures.

Many came just to see this de Havilland

Mosquito on display and fly during the show.

US Auto Industry Contribution: Being of British design and

this particular one Canadian built, one would not think the American

auto industry would not have anything in it. Not so! All of

the two piece formed wood fuselages were built by GM of Canada. At

first glance this would seem odd, until one is reminded it wasn't until

ten years before the start of WWII that automobile bodies were still

being made out of wood, and there was still a lot of experience within

the industry of working with it. Packard supplied the engines and

Nash-Kelvinator in Lansing, MI furnished the propellers. It was

the first propeller contract the Lansing plant received and my grandfather was a foreman

in blade balancing department.

Another rare aircraft many of us came out to see, was this Focke-Wulf

Fw-190A-8.

Goodyear, one of the three major tire suppliers to the auto industry

when WWII started, was one of four auto companies that produced aircraft

during the conflict. This FG-1D is one of 4,007 FG series Corsairs

produced by the company, which also produced all of the airships for the

Navy, along with building major portions of the B-29.

This photo shows three products produced by the auto companies.

Nash-Kelvinator in Kenosha, WI built R-2800 engines for the Corsair and

Chrysler built over 10,000 landing gear for the aircraft. The

difficult to build due to its gull wing configuration wing center

section was built by Willys-Overland, which when the war ended had

produced 3,371 of them.

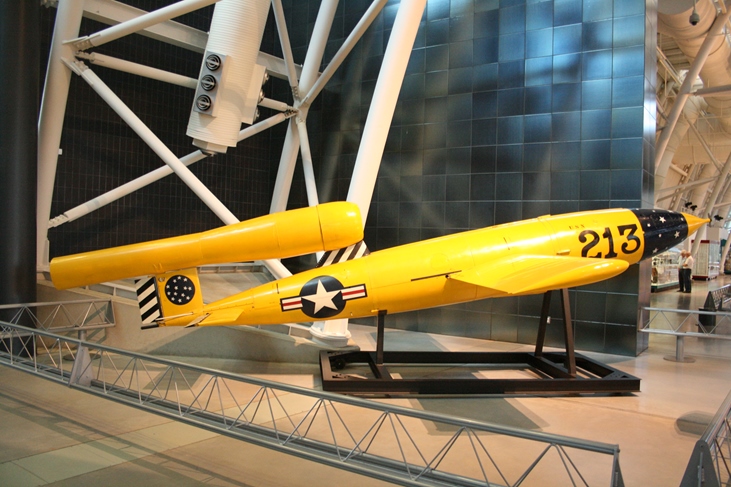

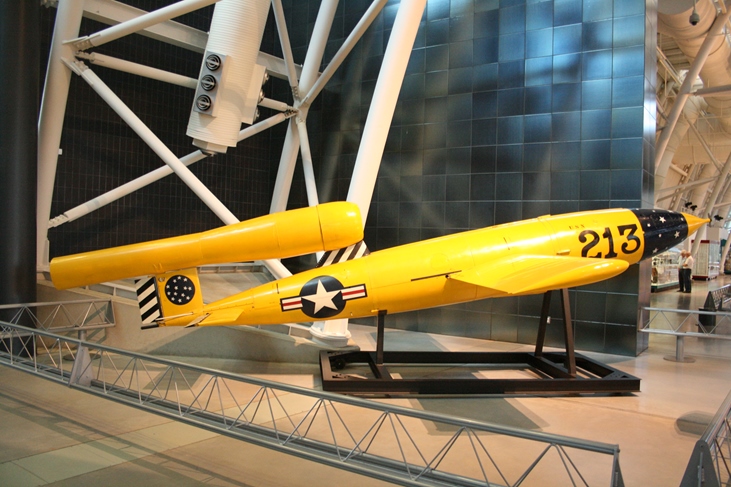

Speaking of Willys-Overland, unfortunately one its most important

products that has been overlooked and just plain forgotten by historians

is that the company made all of the 1,292 airframes for America's first

cruise missile, the JB-2. Also lost in the hype over the Willow

Run Bomber plant is the fact that Ford Motor Company built all 1,292 of

the pulse jet engines. Reversed engineered from the German V-1,

the JB-2 would have been used in the planned invasion of Japan.

P-51B "Old Crow" was one of three Mustangs

that participated in the show.

US Auto Industry Contribution:

Most warbird enthusiasts are well aware that

the Mustang became the fighter it was when powered by the Packard built

Rolls-Royce V-1650 Merlin engine, built on East Grand Boulevard in

downtown Detroit. But they may not be aware that Buick cast the

cylinder blocks or that Graham-Paige machined parts for the engine.

They may also not be aware that Henry Ford was originally approached to

build the engine and refused, as he did not want to work with a foreign

company and country. But Ford did go on to build 57,851 R-2800 engines

at the River Rouge, which was several thousand more engines than Packard

built of the Merlins. Chrysler also refused the work on the Merlin but

that was because it did not want to commit the engineering resources to

converting British drawings and specifications to American ones.

With the demolition of most of the Willow

Run Plant, the former Packard plant in downtown Detroit now has more

still standing of it than what Willow Run has. Actually this

complex of buildings has had more photographs taken of it and more

newspaper/magazine/websites dedicated to it than the Willow Run Plant

could even dream of, as it had become the historic icon of what Detroit

used to be in its prime. The plant was finally purchased from the

City of Detroit in the past year or so by a private investor who is now

working to restore the buildings and lease out the floor space.

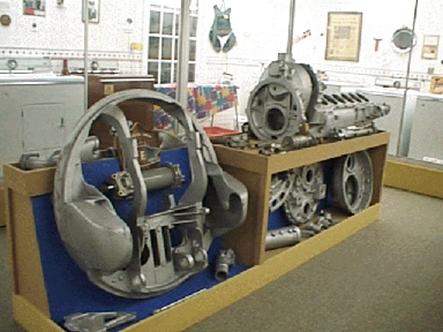

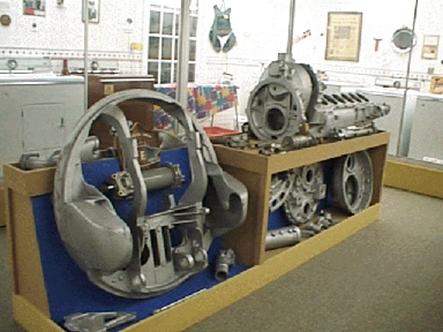

And then during the show announcer Rob Reider was talking about P-51s,

Merlin engines, and Packard when he all of sudden mentioned he had seen

engines in Mustangs with the name "Maytag" on them. I have worked

with Rob at shows as a co-narrator and also listened to him at many

more, and this was the first time I had ever heard him say anything

about "Maytag Merlins". And I was a little confused with Packard

being the only producer in North America of the engine. A little

research has revealed that Maytag actually cast engine blocks and

several other castings for the engine as seen in this photo. The

company cast the name Maytag into each part it made which is why one can

find the that name on a Packard built Merlin. It also looks like

it made casings for the Martin turret.

This group of bombers included two PB4Ys and B-25s. The blue

Privateer has been on outside static display at the Yankee Air Museum

location for many years and the group is now in the process of

restoring the aircraft. One PB4Y at an airshow is extremely rare,

two together is a great job by the show!!

This is the only Privateer currently flying and this is only the second

time I have seen the aircraft on display and then fly, although that was only for a take-off at Chino in 2013.

This is the first time I have seen this

newly restored B-25J owned by the Oklahoma Museum of Flying. Built

a the Fairfax, KS North American plant it has served with the USAAF,

RCAF and the Venezuelan Air Force, was a Gate Guard in Bolivia and

suffered a forced landing in a swamp at Titusville, FL in 1987 after

returning to the US in 1984. It has had a myriad of owners since

then and has now been restored again by the Museum over the past three

years. It is good to see another B-25 back out on the airshow

circuit!

US Auto Industry Contribution:

When the Fairfax plant opened up the Fisher

Body Davison of GM supplied 55% of the content that went into the B-25s

built there which included wings, fuselages, tail assemblies, exhaust

collectors along with forgings, castings and machined parts. Fisher

Body supplied Fairfax from its opening in 1941 through June of 1945.

Ten Fisher Body plants were involved in this endeavor. One of the

Fisher Body plants was also in Lansing, MI, where my mother worked

during the war.

The Morning Battle.

Each year there is a morning and afternoon re-enactor battle. This

year the battle on the ground featured fourteen WWII built half-tracks,

representing Autocar, White and Diamond T.

And each year aircraft fly cover for the soldiers on the ground.

During the morning's event the Mosquito and the Spitfire flew top cover.

Of the three events I have seen the Mosquito fly at, the best and lowest fly-bys were here at Thunder.

On the right is a White M4A1 81mm mortar carrier and an M16 .50 quad

mount on the left.

While not part of the battle, this Dodge WC21

half ton truck was part of the pass in review after the battle and

represents the 404,817 trucks Dodge built during the Second World War,

and the over million trucks built in total by the US auto industry for

the war effort.

The Airshow.

The show opened with an over the head pass by three P-51s, FG-1D and the

Spitfire.

Here is a pass from right to left.

The Spitfire from Military Aviation Museum in Virginia Beach, VA.

When I was at Virginia Beach for the show in May this aircraft was being

worked on and did not fly, so it was a treat to see it fly at Thunder.

The bomber fly-bys with the diverse aircraft and diverse speeds made for

some really great fly-bys, such as this one by the Avro Lancaster.

US Auto Industry Contribution: Packard built engines and

propellers from Nash-Kelvinator in Lansing, MI.

Douglas A-26 Invaders are rather rare at airshows and so it is great to

see this one, owned by Tim Savage and hangared about 60 miles from my

residence, fly for the first time. I hope to see more of the

"Silver Dragon" at airshows around the local area.

US Auto Industry Contribution: Ford not only supplied R-2800 engines for the PV-2 Harpoon

as noted above, but the

A-26, B-26 C-46, P-47 and P-61.

The Lockheed PV-2 Harpoon making one of many

low passes for the day with what looks like the B-29 turning base in the

background. At this time in the show the fast bombers were on a

racetrack pattern closest to the crowd with the slower bombers on the

outside track. The Harpoon has an unmistakable "whistle" to it as

it comes by.

With the parallel tracks in front of the

crowd the spectator can have two aircraft out in front of him at the

same time. Here the B-25J "Hot Gen" from the Canadian Warplane

Heritage Museum as come from behind and passed the slower Privateer as

they pass in front of the crowd. A third aircraft is maneuvering

in the background.

There the Privateer is on the inside track closest to the crowd.

And here the Privateer is on the inside and the B-25 on the outside.

B-17 "Memphis Belle".

US Auto Industry Contribution: Studebaker built

R-1820 engines in South Bend, IN for the B-17 program while Chrysler

built cockpit enclosures for the Flying Fortress at its Los Angeles, CA

plant. Fisher Body Division of GM provided the exhaust manifolds.

Studebaker built 63,789

R-1820 engines for the B-17 and starting in January of 1944 all B-17s

produced came with Studebaker engines, such as the B-17G "Memphis Belle"

above had (Converted to look like a B-17F for the movie Memphis Belle.)

when it came off the Douglas assembly line in Long Beach, CA in April of

1944.

Another first! A "Missing Man"

formation flow with bombers, with an open slot for the "Missing Man".

This is the only time I have seen this done with bombers.

The sky kept getting grayer and grayer as the show progressed but here

is the USAF Heritage Flight as it passes in review.

Last, but not least is the B-29A Superfortess "Fifi", that was at the

show and flew some great low passes for the crowd as shown below.

"Fifi" is an "A" model as were all the B-29s that were built in the

Boeing plant in Renton, WA and, was designated as such because the wings

were attached to the fuselage with internal bracketing, which only left

room for three fuel cells of 1,120 gallons fuel tank, giving it a

shorter range than the B-29s built at Bell, Marietta, GA, Boeing;

Wichita, KS; and Martin at Omaha, NB. These aircraft were

designated as B-29 with no suffix and the wing passed through the

fuselage, allowing for four fuel cells totaling 1,333 gallons. Bell also built a

"B" model, which was the stripped down version with less armor plate and

only the tail gun position for self defense.

US Auto Industry Contribution: Very

significant and extremely important, and overlooked or ignored by

aviation historians.

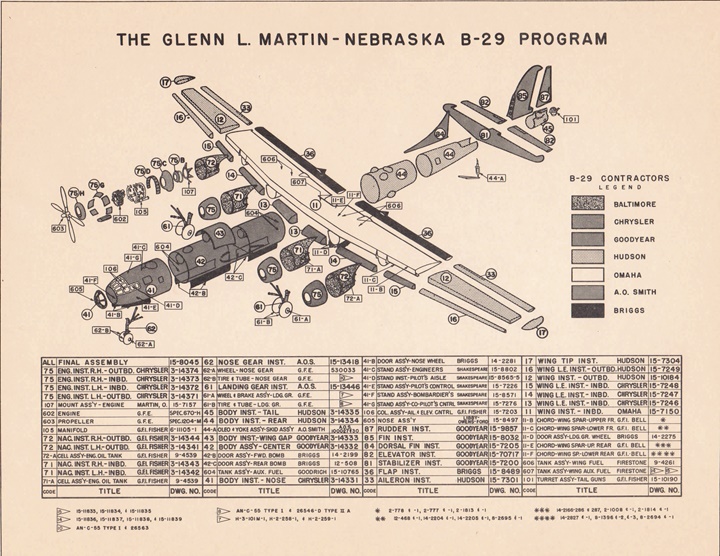

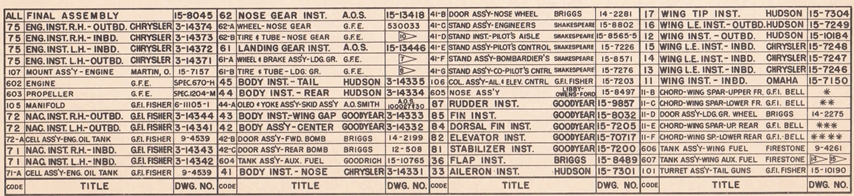

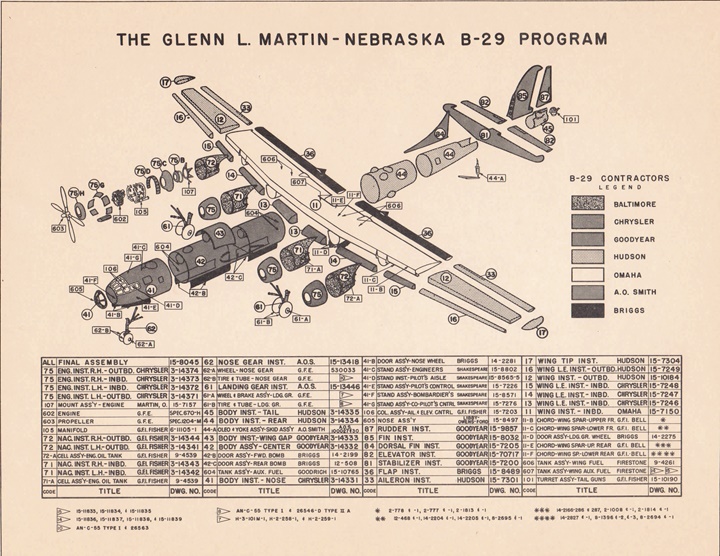

Below is information provided to me courtesy

of Chris Howlett of the UK that he found researching the B-29 for his

new book, The B-29 Manual, which will be published by

Haynes this coming December. His information has been invaluable

in my research and shows which companies were the

major suppliers for the Superfortesses that were built by Martin in

Omaha, NB. Of significance is that Omaha built the Silverplate B-29s,

i.e. "The Enola Gay" and "Bockscar".

This only applies to the Omaha Plant, the

other information I have indicates some of the same parts shown below

were made by other auto companies and delivered to the other B-29

assembly plants.

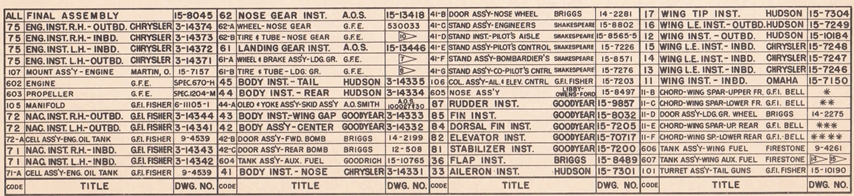

Starting at the front of the fuselage and

working towards the rear of the aircraft, the glass nose section was

built by Libby-Owens-Ford, an automotive glass company, while the

fuselage nose section was built by Chrysler's Plymouth Division in

Detroit. Goodyear in Akron, OH built the two bomb bay fuselage

sections while Briggs, an independent auto body manufacturer in Detroit,

provided the bomb bay doors. The three rear fuselage sections

behind the wings were also built in the city of Detroit by the Hudson

Motor Car Company, which combined in 1954 with Nash to become American

Motors. The entire tail section and the elevators with control

surfaces were made by Goodyear and the tail gunner's position was

manufactured by the Fisher Body Division of GM at Cleveland, OH.

In examining the wing, Martin Omaha provided

the center section while Chrysler provided the inboard leading edges and

Hudson built the outer wing sections, outer leading edges, ailerons and

wing tips and Briggs provided the flaps. All four engine nacelles

and engine oil tanks came from the Fisher Body Division of GM along with the

exhaust manifolds while Omaha built the engine mounts and Chrysler supplied

the engines and engine cowlings.

Firestone provided the main and auxiliary wing

fuel tanks and BF Goodrich the fuselage auxiliary fuel tank.

While this is a Boeing designed aircraft,

there are no major fuselage, wing or rear tail section components

provided by that company. With the exception of the Martin wing

center section, the rest of the wing was supplied by the American

automobile industry.

The next time you stop by Steven F. Udvar-Hazy

Center in Virginia and look at the "Enola Gay" or the National Museum of

the USAF in Ohio and see "Bockscar", remember even though it says Boeing

on it, the fuselage, control surfaces, most of the wing, fuel and oil

tanks and engines were provided courtesy of the American Automobile

Industry.

Titusville (Tico), FL

Virginia Beach, VA

Seymour Johnson AFB, NC

Halls, TN

Warsaw, IN

B-29 Air Power Tour Fort Wayne, IN

Thunder over Michigan, Bellevue MI

|